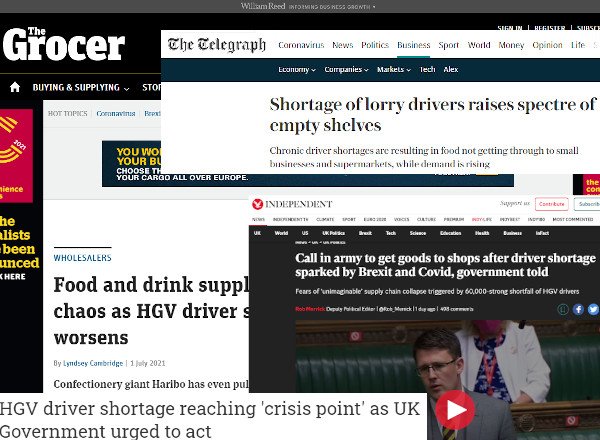

At the beginning of July 2021, British newspapers and trade magazines ran stories about how a national shortage of HGV drivers has been causing severe supply chain disruption across the UK.

On 1st July, for example, The Grocer wrote that “A host of major food and drink manufacturers have issued warnings to their retail and wholesale customers over their service levels as the impact of the driver shortage becomes more tangible.”

On the following day, the BBC reported that a combination of Brexit and the Covid pandemic has led to a shortage of 60,000 lorry drivers. As a result, the country is now witnessing a reduced availability of many common foodstuffs as well as other commodities including fuel.

Supermarkets have issued notices to suppliers noting delays of up to 12 hours in distribution depots and warning that short shelf-life products might be at particular risk.

The present difficulties highlight an important advantage of products with extended shelf lives. If a product has a shelf-life of just 48 hours and it spends 12 of those delayed at a distribution centre, then it’s clear that retailers will face greatly increased risks of that product spoiling before sale. Thus, it’s unsurprising that supermarkets and other retailers are expressing concerns about short-lived products such as bread, fresh cakes, sandwiches and confectionery.

By contrast, longer-lived products minimise those risks and allow business to continue much more as normal. In the case of our doughnuts, 12 hours in a distribution centre is only a small fraction of their 27-day minimum shelf-life, and should create negligible additional risk.

The UK’s present distribution challenges, coupled with a general increase in awareness about the need for waste-minimisation, are all helping to highlight the commercial and environmental benefits associated with longer shelf-life products.